Insulation Technology

INSUPIPE © Global Smart

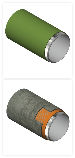

Fusion Bonded Epoxy Polyurethane Aluminum Coating with Heat Tape

The fusion bonded epoxy followed by polyurethane and a layer of Aluminum provides an alternative for preventing hydrate formation in pipelines and providing freeze Protection in addition to the self-regulating heat tracing tape that runs along the length of the pipe to raise or maintain the temperature of the pipe and freeze protection.

Related Standards and Specifications

- EN 253

- ASTM C591

- ANSI/IEEE 844

- ANSI/IEEE 515

Applications

High performance epoxy coated pipe is usually ordered for industrial us ,the long life coated pipe against corrosion ,abrasion and weather is reason beyond it.

HPEC

Concrete coating and epoxy lining is the main specs for underground pushing pipe, a high protection against friction overground is applied on pipe.

CC/EPL

Galvanized concrete coated pipe is used for salty sand underground application , the pipe design life is more than 50 years.

GLCC

MAIN APPLICATIONS

INSUPIPE is used for many applications ,every application is different principal of design ,all considerations changed based on application,below is the most application used:

Three layer coated pipes with polyethylene extruded and concrete lining is the most ordered pipes from us,long life and safe product.

3LPEC/CL

HOT PRODUCTS

| Pipeline Coating |

| Pipeline Lining |

| Detection and Surveillance |

| Concrete Lining |

| Fusion Bonded Epoxy Lining |

| Heat Tape Tracing |

| Skin Effect Heat Tracing |

| Impedance Heat Tracing |

| Ready to Install Leak Detection |

| Built-in Leak Detection |

| Ready To Install Moisture Surveillance |

| Built-In Moisture Surveillance |